Magnetic Particle Testing - (MT)

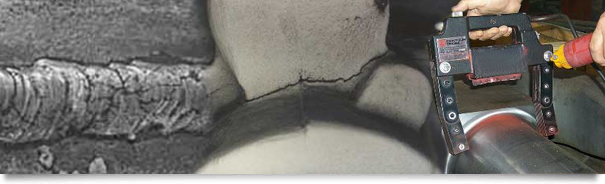

Magnetic particle inspection is a sensitive method of locating surface and some sub-surface defects in Ferro-magnetic components. The basics processing parameters depend on relatively simple concepts. In essence, when a ferromagnetic component is magnetized, magnetic discontinuities that lie in a direction approximately perpendicular to the field direction will result in the formation of strong ‘leakage field’. This leakage field is present at and above the surface of the component, and its presence is visibly detected by the utilization of finely divided magnetic particles. The application of dry or wet particles in a liquid carrier, over the surface of the component, results in a collection of magnetic particle at a discontinuity.

Magnetic particle inspection is a sensitive method of locating surface and some sub-surface defects in Ferro-magnetic components. The basics processing parameters depend on relatively simple concepts. In essence, when a ferromagnetic component is magnetized, magnetic discontinuities that lie in a direction approximately perpendicular to the field direction will result in the formation of strong ‘leakage field’. This leakage field is present at and above the surface of the component, and its presence is visibly detected by the utilization of finely divided magnetic particles. The application of dry or wet particles in a liquid carrier, over the surface of the component, results in a collection of magnetic particle at a discontinuity.

Loknath NDT service gives full prominence on the most important processes that is Magnetic particle inspection (MPI) which is used for the detection of surface and near-surface flaws in ferromagnetic materials. A magnetic field is applied to the specimen, either locally or overall, using a permanent magnet, electromagnet, flexible cables or hand-held prods. If the material is sound, most of the magnetic flux is concentrated below the material's surface. However, if a flaw is present, such that it interacts with the magnetic field, the flux is distorted locally and 'leaks' from the surface of the specimen in the region of the flaw. Fine magnetic particles, applied to the surface of the specimen, are attracted to the area of flux leakage, creating a visible indication of the flaw.